Arc Magnets

- Home

- »

- Sintered NdFeB Magnet

- »

- Arc Magnets

- Sintered NdFeB Magnet

Sintered NdFeB Magnet

Bonded NdFeB Magnets

Samarium Cobalt Magnets

AINiCo Magnets

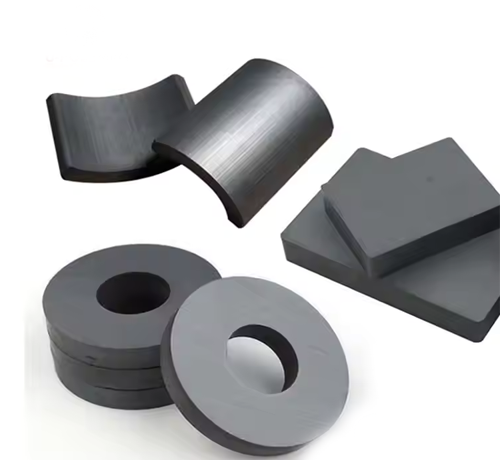

Ferrite Magnets

Flexible Magnet

Magnetic fluid

Magnetic tool

Arc Magnets

- Composite :NdFeB Magnet

- Shape :Arc

- Application :Industrial Magnet

- Processing Service :Cutting, Punching, Moulding

- Product Name :neodymium magnet ac generator Magnet

- Material :NeFeB Magnet

- Hcb: 13.24 KOe

- Working temperature :80~350C Degree Max

- Application :motor, generator, and magnetic bearing

- Single package size: 34X24X18 cm

- Single gross weight: 0.021 kg

Shipping

Shipping fee and delivery date to be negotiated. Chat with sales now for more details.

Product Description

N42SH Neodymium Magnet

N42SH with working temperature of 302 degree Fahrenheit or 150 degree celsius . It is magnetized through the thickness with the

north pole on the inner diameter. The 8 pieces of this arc magnets can form a circle with OD=1.5″, ID=1.25″ and height =0.75″.

* Hcb: 13.24 KOe

* Hcj: 13.42 KOe

* (BH)max: 39.5MGOe

* Working Temperature: 150 degree Centigrade or 302 Fahrenheit

* Magnetization: through thickness. North pole is on the inner arc.

* Coating: Ni+Cu+Ni plated. the best coating available.

* Application: motor, generator, and magnetic bearing

Table of Products

| Grade | Residual magnetism | Coercive field strength | Energy product | Max. operational temp. |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Br | bHc | iHc | (BxH)max | ||||||

| Gauss (G) | Tesla (T) | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ | °C | |

| N30 | 10800-11200 | 1.08-1.12 | 9.8-10.5 | 780-836 | ≥12 | ≥955 | 28-30 | 223-239 | ≤80 |

| N33 | 11400-11700 | 1.14-1.17 | 10.3-11 | 820-876 | ≥12 | ≥955 | 31-33 | 247-263 | ≤80 |

| N35 | 11700-12100 | 1.17-1.21 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 33-35 | 263-279 | ≤80 |

| N38 | 12200-12600 | 1.22-1.26 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 36-38 | 287-303 | ≤80 |

| N40 | 12600-12900 | 1.26-1.29 | 10.5-12.0 | 860-955 | ≥12 | ≥955 | 38-40 | 303-318 | ≤80 |

| N42 | 12900-13200 | 1.29-1.32 | 10.8-12.0 | 860-955 | ≥12 | ≥955 | 40-42 | 318-334 | ≤80 |

| N45 | 13200-13700 | 1.32-1.37 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 43-45 | 342-358 | ≤80 |

| N48 | 13700-14200 | 1.37-1.42 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 45-48 | 358-382 | ≤80 |

| N50 | 14000-14600 | 1.40-1.46 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 47-51 | 374-406 | ≤80 |

| N52 | 14200-14700 | 1.42-1.47 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 48-53 | 380-422 | ≤80 |

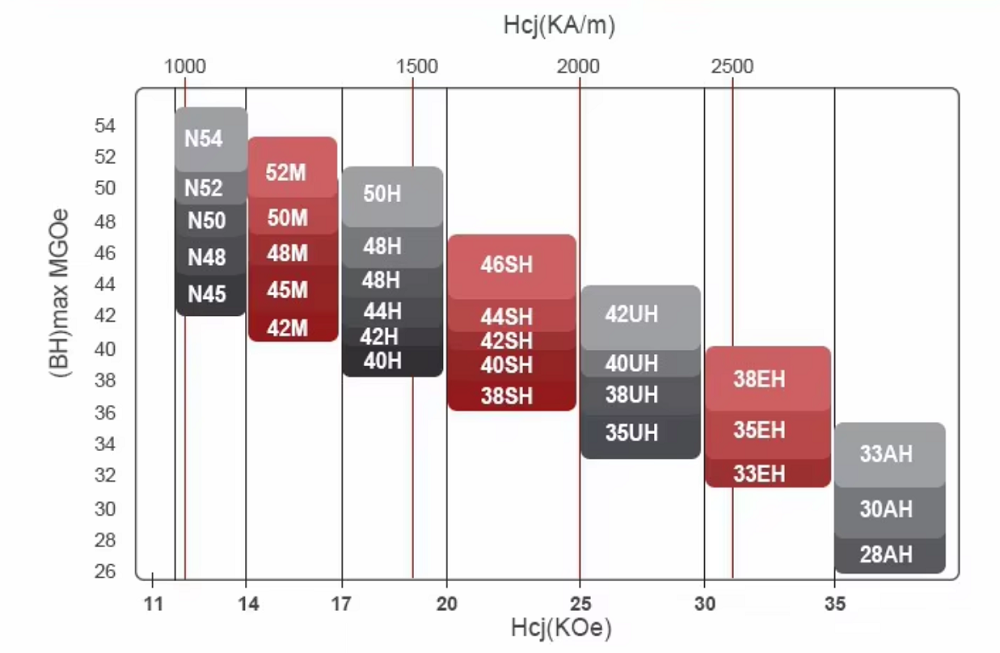

Grades of Neodymium Magnet

Neodymium magnets are all graded by the material they are made of. As a very general rule, the higher the grade (the number following the ‘N’), the stronger the magnet. The highest grade of neodymium magnet currently available is N52. Any letter following the grade refers to the temperature rating of the magnet. If there are no letters following the grade, then the magnet is standard temperature neodymium. The temperature ratings are standard (no designation) – M – H – SH – UH – EH.

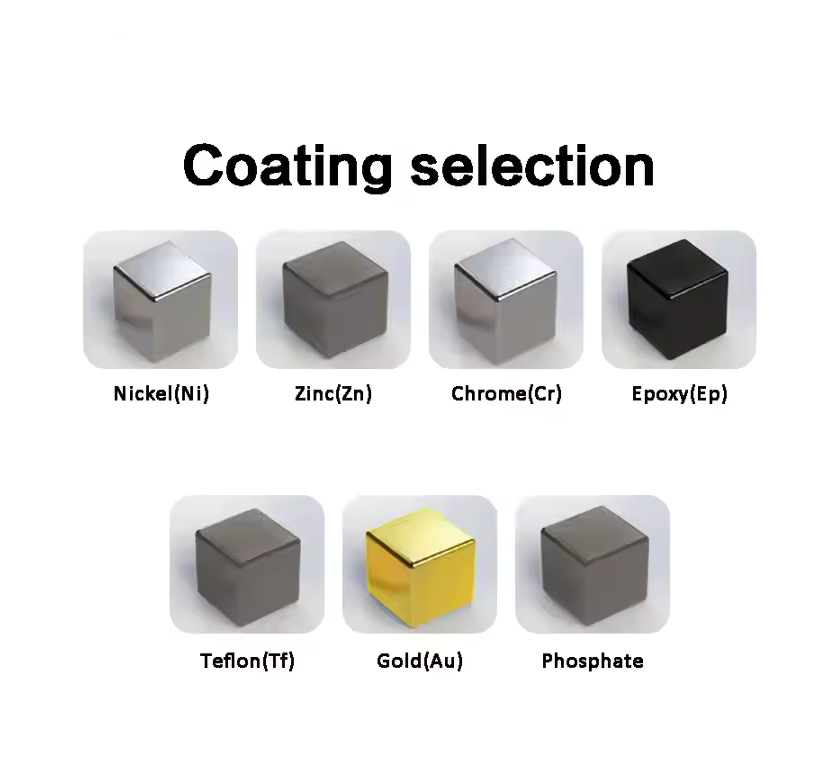

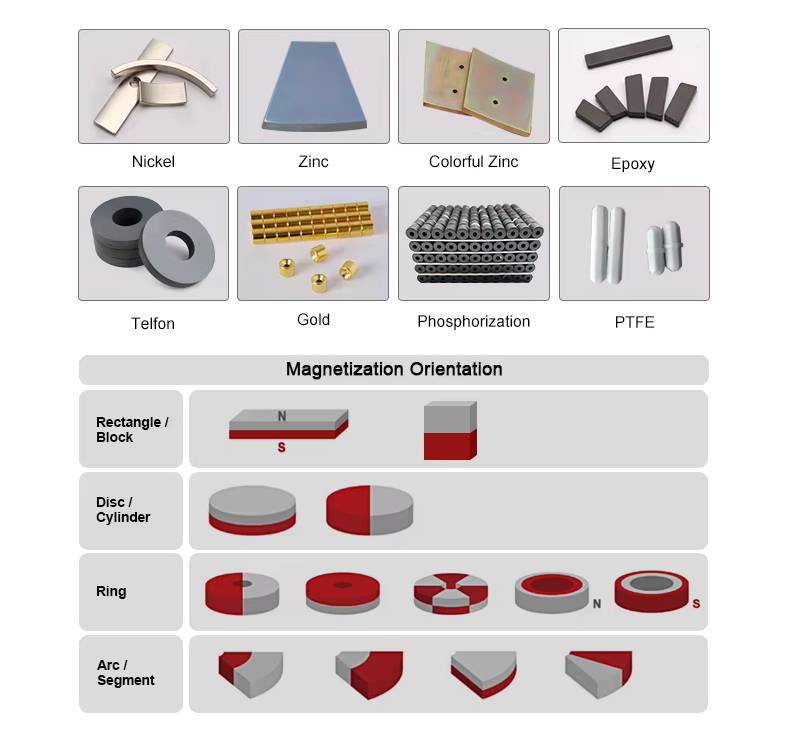

Platings/Coatings

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold. Our gold plated magnets are actually quadruple plated with nickel, copper, nickel and a top coating of gold.

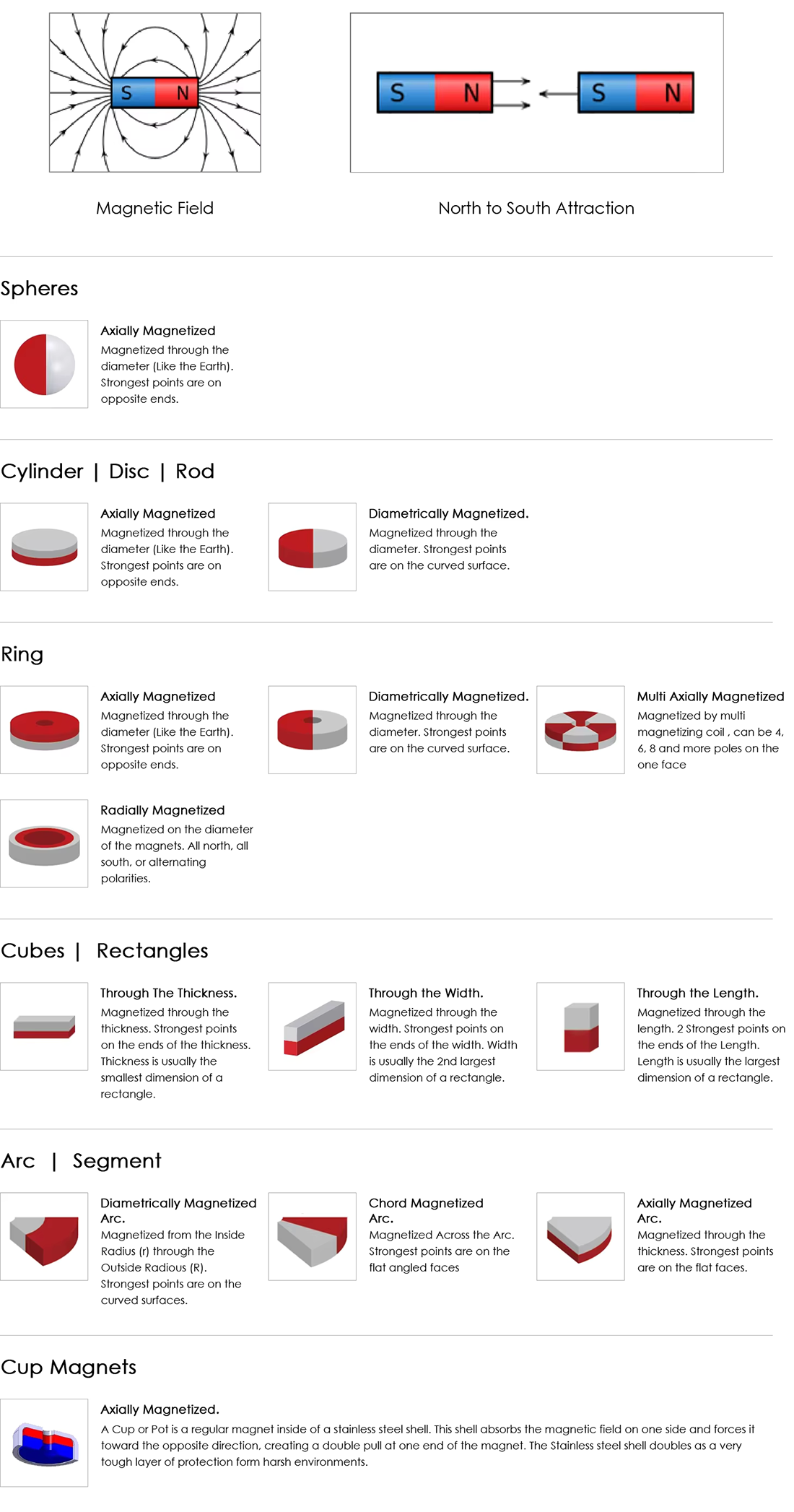

Magnetization Plating & Orientation

Why choose us ?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Advanced Facilities

Excellent production equipment

Advanced Facilities

Excellent production equipment Focus on the magnetic materialindustry to become a new bench.mark of the industry with integraton,innovation and brand power

Product Testing

Strict product testing process With the force of technologicalinnovation and industry integra-tion to promote the developmentof magnetic material application,continue to create value forcustomers

Engineering Service

Meet all customer needs All for customers, core than a promiseCustomer-Oriented CollaborationResponsibility Innovation

Our certifications

Frequently Asked Questions

1. Q: Are you trading company or manufacturer ?

A: We are factory.

2. Q: How long is your delivery time?

3. Q: Do you provide samples ? is it free or extra ?

4. Q: What is your terms of payment ?

Related Products

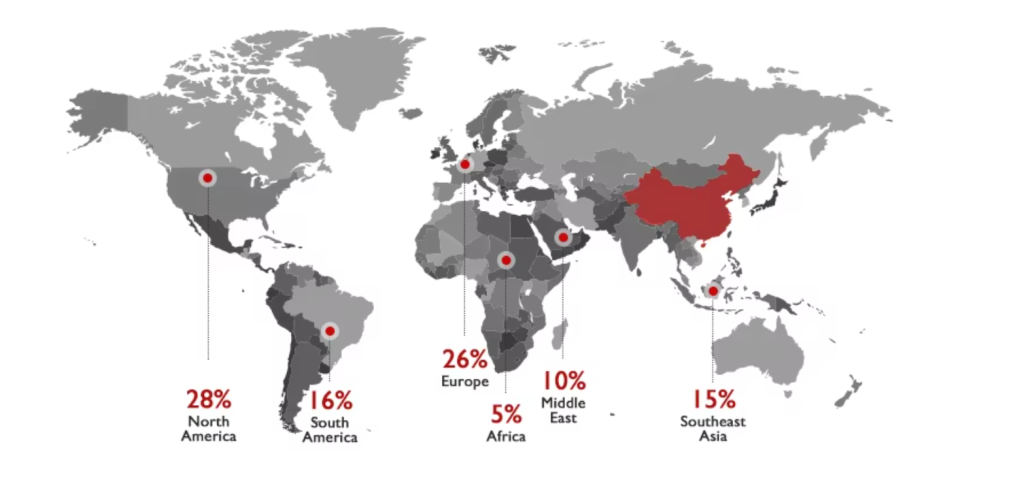

Thank You for Your Attention to Shenzhen Xinhongchang Magnetic Material Co., Ltd.

Send us your needs for your business, we have professional service team to answer you !