Block Magnets

- Home

- »

- Sintered NdFeB Magnet

- »

- Block Magnets

- Sintered NdFeB Magnet

Sintered NdFeB Magnet

Bonded NdFeB Magnets

Samarium Cobalt Magnets

AINiCo Magnets

Ferrite Magnets

Flexible Magnet

Magnetic fluid

Magnetic tool

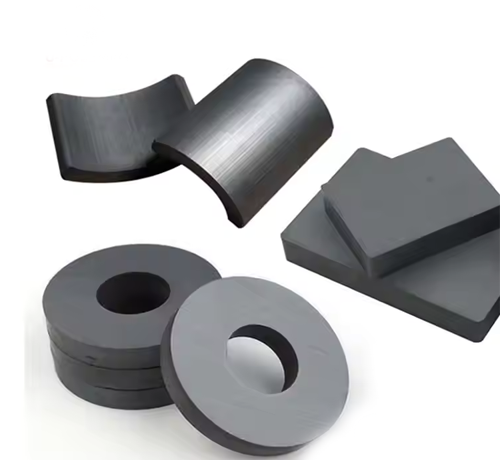

Block Magnets

- Composite :Neodymium Magnet

- Shape :Rectangular

- Application :Industrial Magnet

- Processing Service :Cutting, Punching, Moulding

- tolerance :+/-0.05mm

- Sample Time: About 10-15 days

- Payment Terms :T/T,Western Union,Paypal

- Single package size: 35X25X15 cm

- Single gross weight: 1.500 kg

Shipping

Shipping fee and delivery date to be negotiated. Chat with sales now for more details.

Product Description

N35-N52 High Quality Neodymium Diametrically Magnetized neodymium permanent magnet levitating

Our neodymium magnets use the most advanced production technology and materials, and have achieved international standards in terms of strength, temperature stability, and service life. Our products have the following characteristics:

1. Strong magnetic force – our neodymium magnets have very high magnetic properties and can support and attract large weight loads.

2. High temperature stability – our neodymium magnets can maintain stable magnetic properties even in high-temperature environments.

3. Long service life – our neodymium magnets have undergone special processing technology and can be used continuously in different environments for many years without failure.

4. Ultra-fine processing accuracy – our neodymium magnets can be processed into various shapes and sizes through advanced production technology and equipment with high precision.

Our neodymium magnet products include square, arc, cylindrical, ring, fan-shaped, ball-shaped, and other shapes, covering all possible application areas such as motors, generators, compressors, sensors, and medical equipment. We can provide customized production according to the actual needs of customers, meeting international quality standards and providing perfect after-sales service.

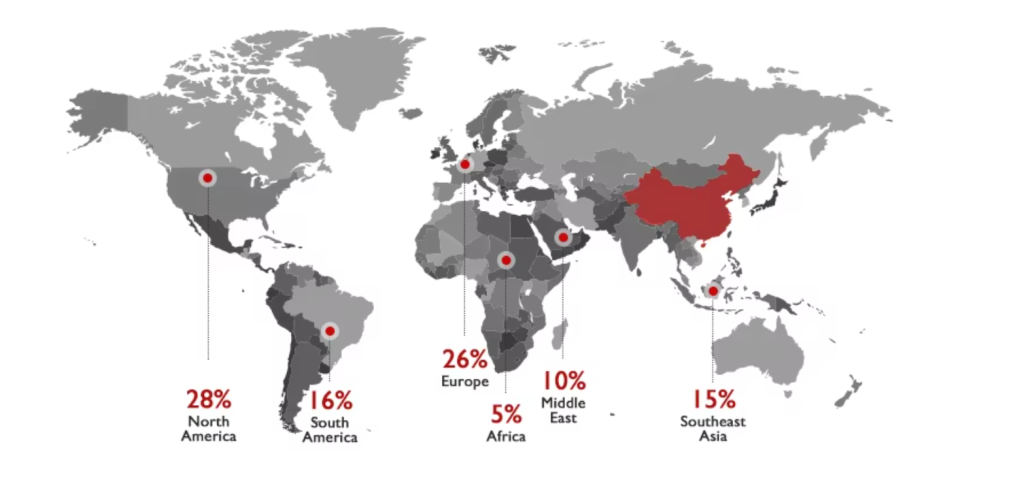

We firmly believe that our neodymium magnets will be your best choice, whether you need a high-performance magnet or a custom magnet solution. We have 20 years of production experience and reputation, and we welcome you to contact us for more information.

Table of Products

| Grade | Residual magnetism | Coercive field strength | Energy product | Max. operational temp. |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Br | bHc | iHc | (BxH)max | ||||||

| Gauss (G) | Tesla (T) | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ | °C | |

| N30 | 10800-11200 | 1.08-1.12 | 9.8-10.5 | 780-836 | ≥12 | ≥955 | 28-30 | 223-239 | ≤80 |

| N33 | 11400-11700 | 1.14-1.17 | 10.3-11 | 820-876 | ≥12 | ≥955 | 31-33 | 247-263 | ≤80 |

| N35 | 11700-12100 | 1.17-1.21 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 33-35 | 263-279 | ≤80 |

| N38 | 12200-12600 | 1.22-1.26 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 36-38 | 287-303 | ≤80 |

| N40 | 12600-12900 | 1.26-1.29 | 10.5-12.0 | 860-955 | ≥12 | ≥955 | 38-40 | 303-318 | ≤80 |

| N42 | 12900-13200 | 1.29-1.32 | 10.8-12.0 | 860-955 | ≥12 | ≥955 | 40-42 | 318-334 | ≤80 |

| N45 | 13200-13700 | 1.32-1.37 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 43-45 | 342-358 | ≤80 |

| N48 | 13700-14200 | 1.37-1.42 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 45-48 | 358-382 | ≤80 |

| N50 | 14000-14600 | 1.40-1.46 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 47-51 | 374-406 | ≤80 |

| N52 | 14200-14700 | 1.42-1.47 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 48-53 | 380-422 | ≤65 |

Magnet Plating and Coating Options

- Oxidization (Rust):NdFeB magnets will oxidize(rust) if left exposed. When a plating wears down or cracks, the exposed area will oxidize. An oxidized area will not result in complete degradation of the magnet, only the oxidized area will lose its strength. However the magnet will lose some structural integrity and become more susceptible to breakage.

- Durability: Depending on shape, permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

- Harsh Environments:Platings vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating.

SmCo Block Magnet Applications

Neodymium magnets are known for their exceptionally high magnetic properties and are widely used in various industries due to their strength, durability, and versatility. Here are some of the application areas where neodymium magnets are commonly used:

equipment, and metal detectors.

Energy Sector

Research and Education

Industrial Manufacturing

Medical Field

Why choose us ?

Advanced Facilities

Excellent production equipment

Advanced Facilities

Excellent production equipment Focus on the magnetic materialindustry to become a new bench.mark of the industry with integraton,innovation and brand power

Product Testing

Strict product testing process With the force of technologicalinnovation and industry integra-tion to promote the developmentof magnetic material application,continue to create value forcustomers

Engineering Service

Meet all customer needs All for customers, core than a promiseCustomer-Oriented CollaborationResponsibility Innovation

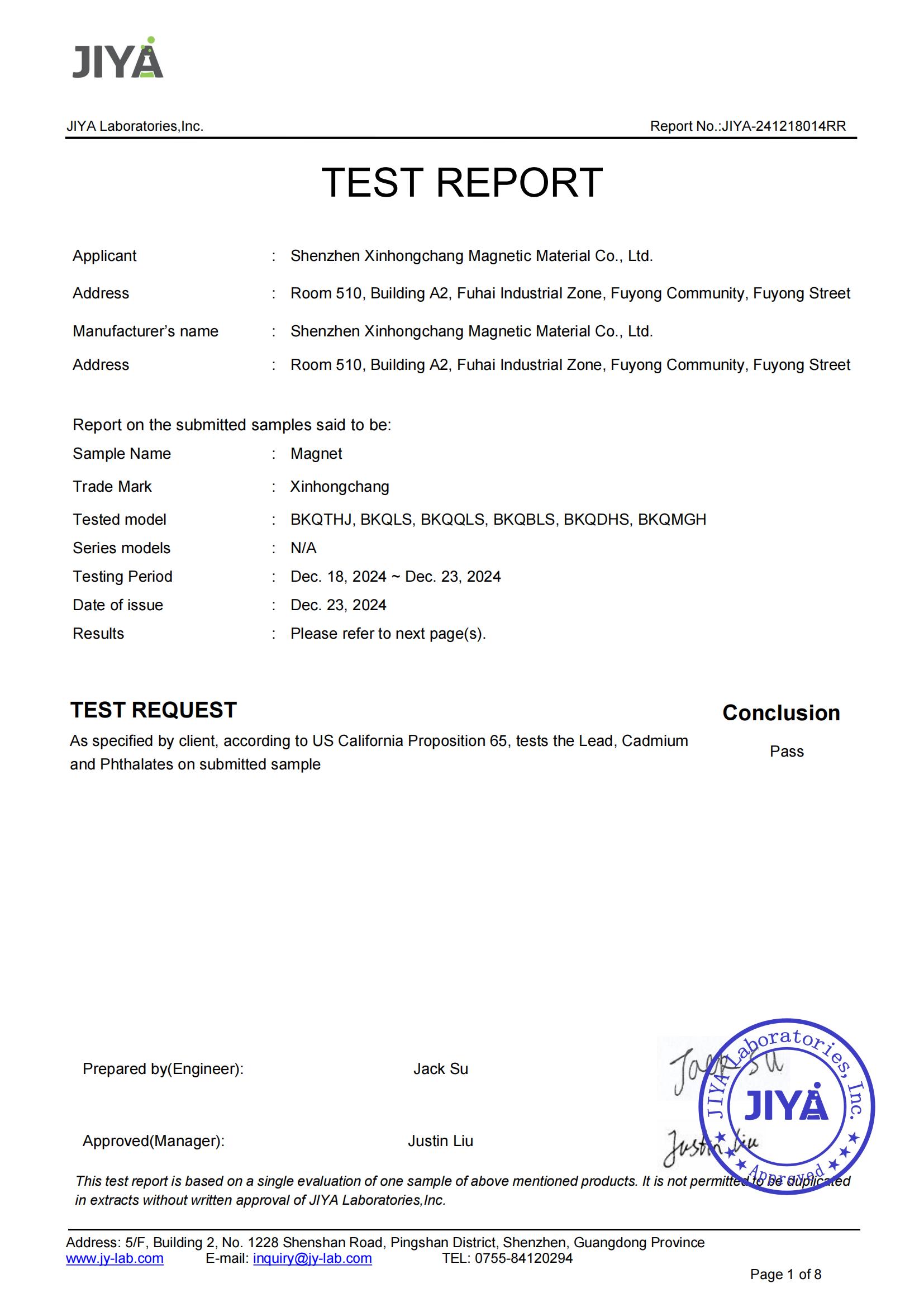

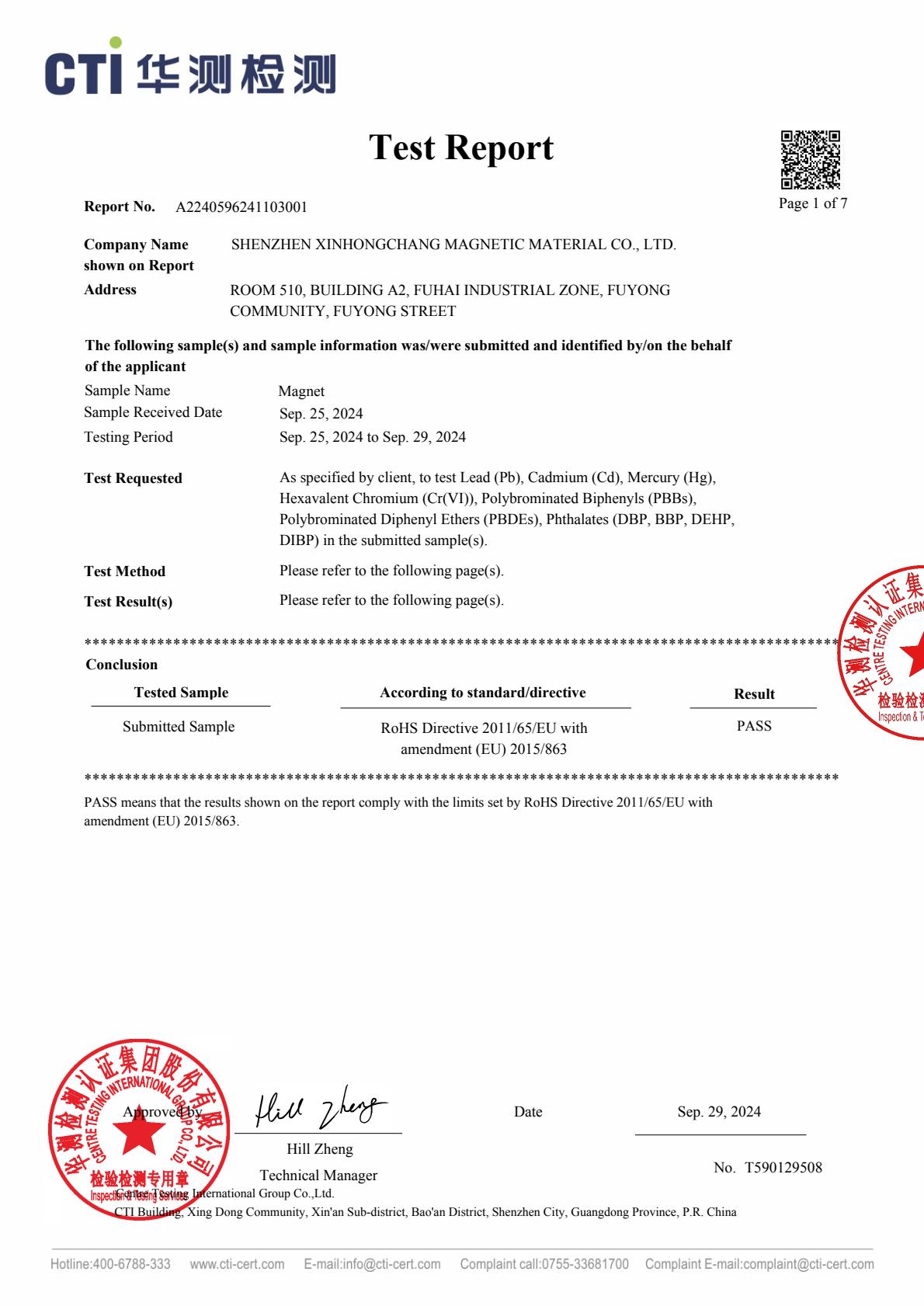

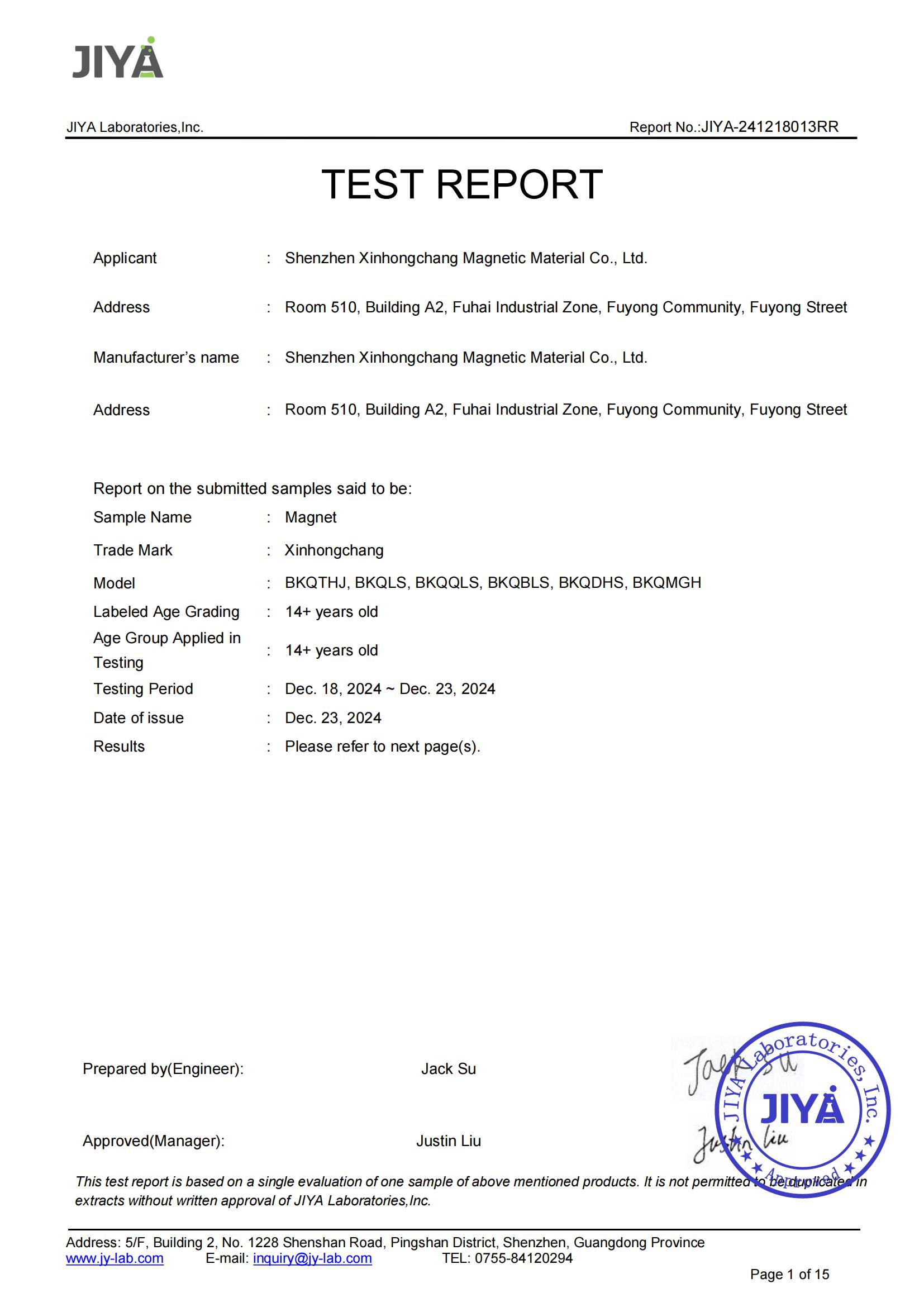

Our certifications

Frequently Asked Questions

1. Q: Are you trading company or manufacturer ?

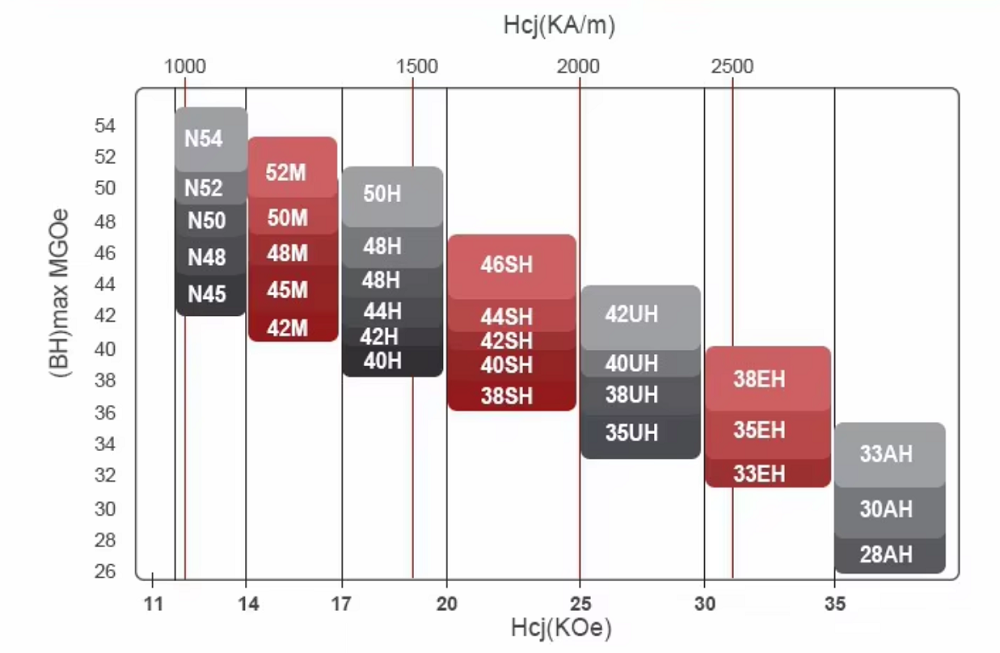

- Standard NdFeB magnets (e.g., N35, N38) are generally suitable for temperatures up to 80°C to 100°C.

- High-temperature grades (e.g., N35M, N38H) can operate at higher temperatures, with some grades like N35AH or N38UH capable of withstanding temperatures up to 200°C.

2. Q: How long is your delivery time?

- Select the right grade: Choose a magnet grade suitable for your operating temperature and environment.

- Avoid high temperatures: Keep the magnets within their specified temperature range to prevent thermal demagnetization.

- Shielding: Use magnetic shielding materials to protect the magnets from strong external magnetic fields.

- Proper handling: Handle the magnets carefully to avoid mechanical stress, which can cause micro-cracks and affect magnetic performance.

- Storage: Store magnets in a cool, dry place, away from strong magnetic fields and corrosive environments.

3. Q: Do you provide samples ?

- Coating: Apply protective coatings such as nickel plating, zinc plating, or epoxy coating to protect the magnet from moisture and corrosive environments.

- Environment control: Store and use the magnets in dry environments to minimize exposure to humidity.

- Sealing: For applications in highly corrosive environments, consider sealing the magnets with additional protective layers or using corrosion-resistant materials in the surrounding structure.

- Standard NdFeB magnets (e.g., N35, N38) are generally suitable for temperatures up to 80°C to 100°C.

- High-temperature grades (e.g., N35M, N38H) can operate at higher temperatures, with some grades like N35AH or N38UH capable of withstanding temperatures up to 200°C.

4. Q: What is your terms of payment ?

If you have another question, pls feel free to contact us.

Related Products

Thank You for Your Attention to Shenzhen Xinhongchang Magnetic Material Co., Ltd.

Send us your needs for your business, we have professional service team to answer you !