Disc Magnets

- Home

- »

- Sintered NdFeB Magnet

- »

- Disc Magnets

- Sintered NdFeB Magnet

Sintered NdFeB Magnet

Bonded NdFeB Magnets

Samarium Cobalt Magnets

AINiCo Magnets

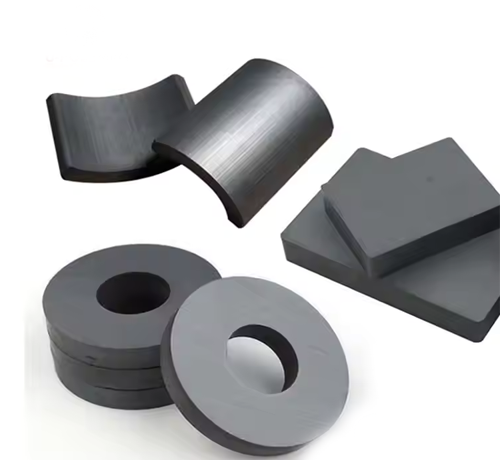

Ferrite Magnets

Flexible Magnet

Magnetic fluid

Magnetic tool

Disc Magnets

- Product Name :Neodymium magnet

- Shape :Disc

- Application :Industrial Magnet

- Coating :Epoxy.Black Epoxy. Nickel.Silver.etc

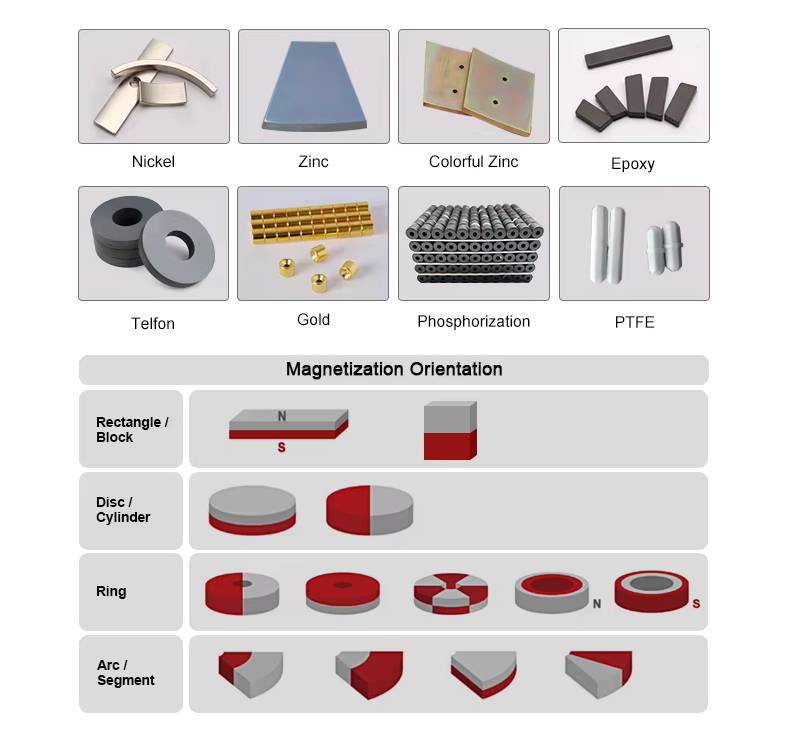

- Magnetism direction :Thickness. Axial. Radial

- Usage :Industrial Usage

- Magnet shape :Round,Disc,Block,Ring,Arc Or special customization

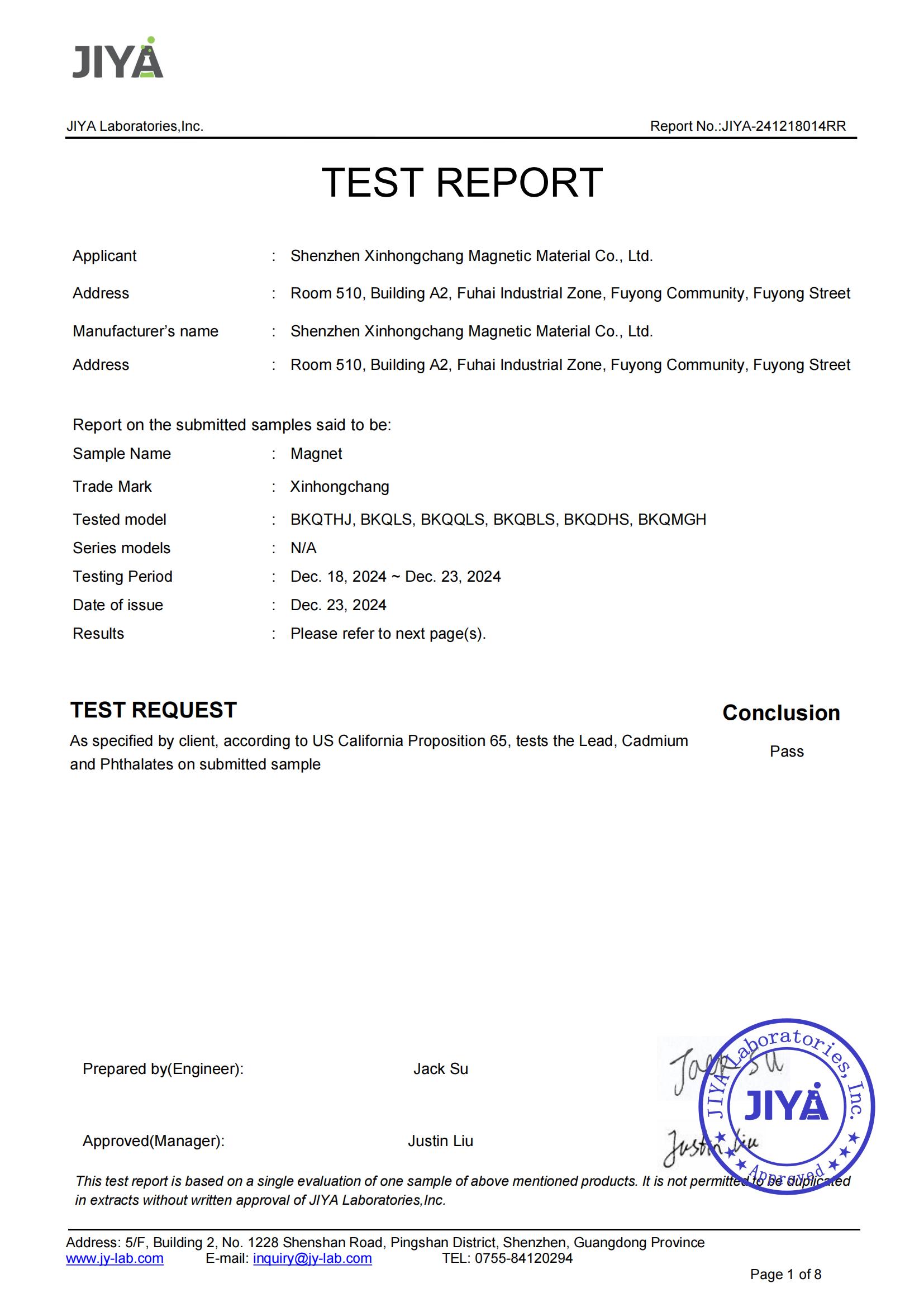

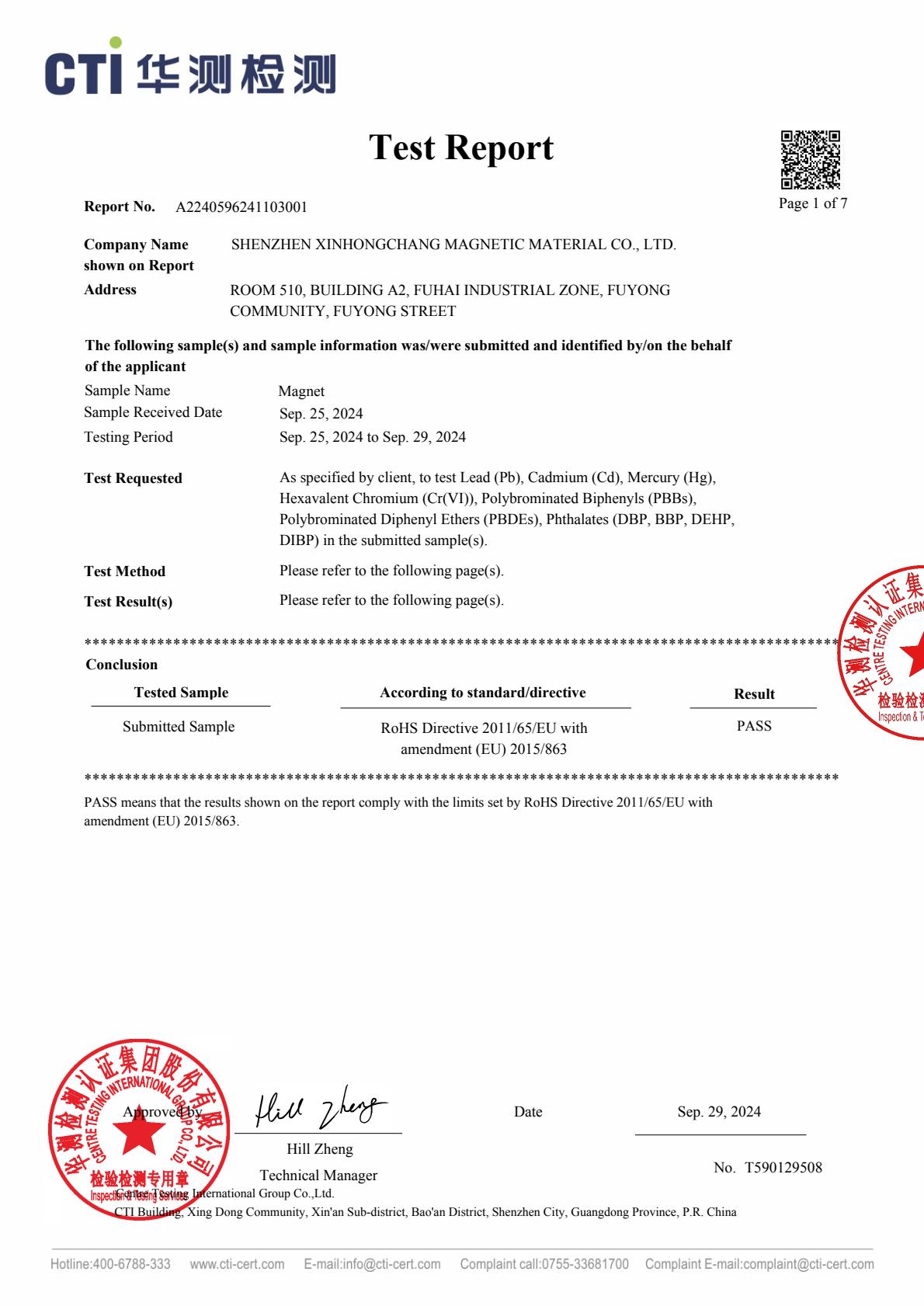

- Certification :ISO 9001: 2015 ROHS REACH CE

- Single package size: 34X24X18 cm

- Single gross weight: 0.021 kg

Shipping

Shipping fee and delivery date to be negotiated. Chat with sales now for more details.

Product Description

Professional Manufacturer Wholesale Price 15X2mm Disc Magnet

Discover the pinnacle of magnetic expertise with our Professional Manufacturer Wholesale Price 15X2mm Disc Magnet. As a leader in magnet manufacturing, we bring you an exceptional product that combines precision, power, and affordability.

1.Unparalleled Craftsmanship

Our 15X2mm Disc Magnet is a testament to the artistry and precision that define our products. Crafted with meticulous attention to detail, this magnet embodies the perfect balance of size and strength, making it a versatile choice for various applications.

2. Wholesale Advantage

Benefit from our direct manufacturing capabilities and unlock wholesale prices without compromising on quality. Our commitment to excellence ensures that you receive a superior product at a price that meets your budgetary needs.

3. Compact Powerhouse

Measuring 15mm in diameter and 2mm in thickness, this disc magnet boasts a compact form factor that belies its powerful magnetic force. Its unassuming size makes it ideal for discreet yet impactful applications across industries.

4. Endless Possibilities

From crafting to electronics, our 15X2mm Disc Magnet brings a touch of magnetism to a wide range of projects. Whether you’re exploring new DIY endeavors or enhancing industrial processes, this magnet opens doors to creativity.

5. Reliability at its Core

Built to last, our disc magnet is engineered from high-quality materials, ensuring a reliable and consistent magnetic performance over time. Rely on it for stability and dependability, no matter the application.

Table of Products

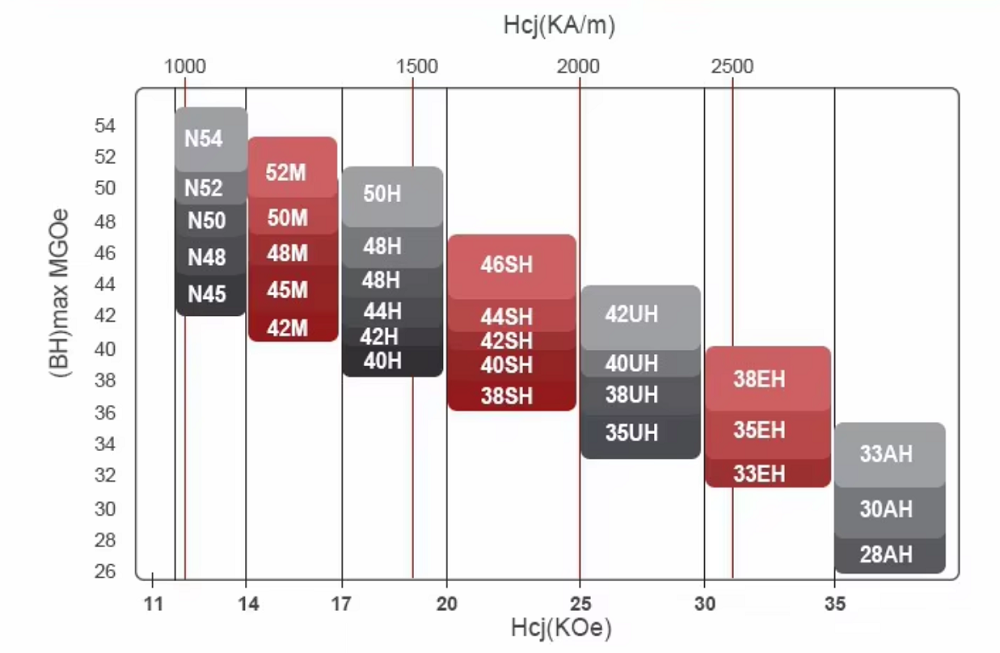

| Grade | Residual magnetism | Coercive field strength | Energy product | Max. operational temp. |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Br | bHc | iHc | (BxH)max | ||||||

| Gauss (G) | Tesla (T) | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ | °C | |

| N30 | 10800-11200 | 1.08-1.12 | 9.8-10.5 | 780-836 | ≥12 | ≥955 | 28-30 | 223-239 | ≤80 |

| N33 | 11400-11700 | 1.14-1.17 | 10.3-11 | 820-876 | ≥12 | ≥955 | 31-33 | 247-263 | ≤80 |

| N35 | 11700-12100 | 1.17-1.21 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 33-35 | 263-279 | ≤80 |

| N38 | 12200-12600 | 1.22-1.26 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 36-38 | 287-303 | ≤80 |

| N40 | 12600-12900 | 1.26-1.29 | 10.5-12.0 | 860-955 | ≥12 | ≥955 | 38-40 | 303-318 | ≤80 |

| N42 | 12900-13200 | 1.29-1.32 | 10.8-12.0 | 860-955 | ≥12 | ≥955 | 40-42 | 318-334 | ≤80 |

| N45 | 13200-13700 | 1.32-1.37 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 43-45 | 342-358 | ≤80 |

| N48 | 13700-14200 | 1.37-1.42 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 45-48 | 358-382 | ≤80 |

| N50 | 14000-14600 | 1.40-1.46 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 47-51 | 374-406 | ≤80 |

| N52 | 14200-14700 | 1.42-1.47 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 48-53 | 380-422 | ≤65 |

Magnet Plating and Coating Options

- Oxidization (Rust) :NdFeB magnets will oxidize(rust) if left exposed. When a plating wears down or cracks, the exposed area will oxidize. An oxidized area will not result in complete degradation of the magnet, only the oxidized area will lose its strength. However the magnet will lose some structural integrity and become more susceptible to breakage.

- Durability: Depending on shape, permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

- Harsh Environments:Platings vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating.

Magnet Plating and Coating Options

A Magnetic field is an invisible flux moving from one end of the magnet to the other. Shown in Figure1. The flux consists of moving or spinning electrically charged particles invisible to the eye. If the max working temperature meet the requirement ,permanent magnets can retain the magnetic field for very long time even forever. Magnets have potential energy which means that they have the ability to conserve energy. The magnet will display or release some of its conserved energy when pulling towards or attaching to something then conserve or store the energy that the user exerts when pulling it off.

Common Applications for Permanent Magnets

Neodymium magnets are strong magnets,frequently used for many types of sectors, commercial, industrial & technical applications where strong permanent magnets are required. Due to their high-magnetic strength, components that previously had to be large and heavy can now be miniaturized by using Neodymium magnet material.Common Applications: holding systems requiring very high holding forces, sensors, reed switches, hard disc drives, audio equipment, acoustic pick-ups, headphones & loudspeakers, MRI scanners, magnetically coupled pumps · motors & generators, magnetic tool holders, magnetic bearings, door catches, dental instruments, medical devices, magnetic separators, lifting machinery, crafts & model making, hanging artwork, levitation devices, POP displays, commercial signage, packaging closures, jewelry clasps & more.

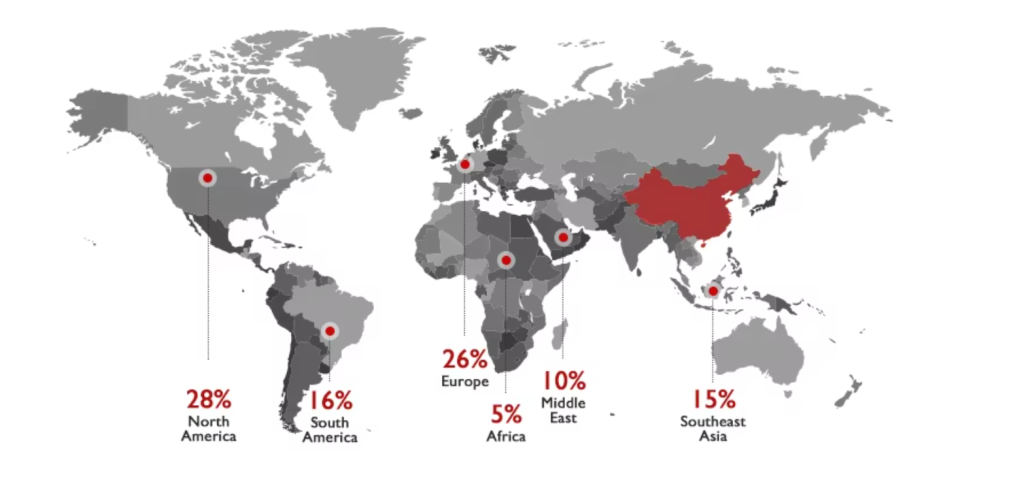

Why choose us ?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Advanced Facilities

Excellent production equipment

Advanced Facilities

Excellent production equipment Focus on the magnetic materialindustry to become a new bench.mark of the industry with integraton,innovation and brand power

Product Testing

Strict product testing process With the force of technologicalinnovation and industry integra-tion to promote the developmentof magnetic material application,continue to create value forcustomers

Engineering Service

Meet all customer needs All for customers, core than a promiseCustomer-Oriented CollaborationResponsibility Innovation

Our certifications

Frequently Asked Questions

1. Q: What is the maximum operating temperature for Sintered NdFeB Magnets?

- Standard NdFeB magnets (e.g., N35, N38) are generally suitable for temperatures up to 80°C to 100°C.

- High-temperature grades (e.g., N35M, N38H) can operate at higher temperatures, with some grades like N35AH or N38UH capable of withstanding temperatures up to 200°C.

2. Q: How can I prevent demagnetization of Sintered NdFeB Magnets?

- Select the right grade: Choose a magnet grade suitable for your operating temperature and environment.

- Avoid high temperatures: Keep the magnets within their specified temperature range to prevent thermal demagnetization.

- Shielding: Use magnetic shielding materials to protect the magnets from strong external magnetic fields.

- Proper handling: Handle the magnets carefully to avoid mechanical stress, which can cause micro-cracks and affect magnetic performance.

- Storage: Store magnets in a cool, dry place, away from strong magnetic fields and corrosive environments.

3. Q: Are Sintered NdFeB Magnets susceptible to corrosion?

- Coating: Apply protective coatings such as nickel plating, zinc plating, or epoxy coating to protect the magnet from moisture and corrosive environments.

- Environment control: Store and use the magnets in dry environments to minimize exposure to humidity.

- Sealing: For applications in highly corrosive environments, consider sealing the magnets with additional protective layers or using corrosion-resistant materials in the surrounding structure.

- Standard NdFeB magnets (e.g., N35, N38) are generally suitable for temperatures up to 80°C to 100°C.

- High-temperature grades (e.g., N35M, N38H) can operate at higher temperatures, with some grades like N35AH or N38UH capable of withstanding temperatures up to 200°C.

4. Q: Can Sintered NdFeB Magnets be customized in terms of shape and size?

- Blocks

- Cylinders

- Rings

- Arcs

- Custom geometries

- Standard NdFeB magnets (e.g., N35, N38) are generally suitable for temperatures up to 80°C to 100°C.

- High-temperature grades (e.g., N35M, N38H) can operate at higher temperatures, with some grades like N35AH or N38UH capable of withstanding temperatures up to 200°C.

5. Q: How should I handle and store Sintered NdFeB Magnets to maintain their performance?

- Handling:

- Use gloves: Wear gloves to prevent oils from your skin from transferring to the magnets, which can affect their surface and coating.

- Avoid dropping: Handle the magnets carefully to avoid mechanical stress and potential damage.

- Separate storage: Store magnets separately to prevent them from attracting each other, which can cause chipping or demagnetization.

- Storage:

- Dry environment: Store magnets in a cool, dry place to prevent corrosion.

- Away from magnetic fields: Keep magnets away from strong external magnetic fields to prevent demagnetization.

- Labeling: Clearly label the magnets with their grade, orientation, and other relevant information to avoid confusion.

- Standard NdFeB magnets (e.g., N35, N38) are generally suitable for temperatures up to 80°C to 100°C.

- High-temperature grades (e.g., N35M, N38H) can operate at higher temperatures, with some grades like N35AH or N38UH capable of withstanding temperatures up to 200°C.

Related Products

Thank You for Your Attention to Shenzhen Xinhongchang Magnetic Material Co., Ltd.

Send us your needs for your business, we have professional service team to answer you !